My main sewing machine is a JoAnn Sonata, and it has a bit of a history. It’s technically a vintage machine, I think, having been made in the early 1980s and then promptly forgotten by the entire world. Every now and then I get an email from someone who bought one at a yard sale, thanking me profusely for scanning and uploading the user manual, but for years the only Google hits for it were ones I’d written myself.

My machine, photographed in 2006

To complicate matters even further, my machine began life as my sister-in-law’s grandmother’s machine, which was gifted to me well over a decade ago when my mom brought it over as checked luggage on a flight from the States. So on top of being some random, vintage brand no one’s ever heard of, it’s also the wrong voltage (I run it through a voltage converter).

Considering the sheer volume of use it sees, the machine does so well, and I have no intention of ever replacing it so long as I can keep repairing it. I mean, I clean it fairly regularly, but I hardly ever oil it, and it only went in for its first ever service (during my tenure, anyway) last winter when the foot pedal stopped responding. My man at Maury Sewing was able to repair the foot pedal then, but advised that if it failed again, I should buy a replacement pedal from the States and just swap out the plug end (he looked into replacing the motor with a 220v one but couldn’t find one to fit the body on short notice).

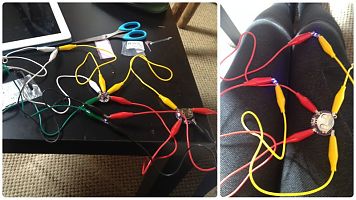

The repairs lasted a good six months, but again recently, I found myself having to pump the pedal to get it to respond, and even then, it’d only go at maximum speed which isn’t exactly ideal. So I hunted on US eBay and found a really similar-looking vintage, metal food pedal in 110v wiring, with the thought of recruiting James to rewire the old plug end onto the new-to-me pedal.

The eBay replacement (top) and my original (bottom)

But our friend Alex happened to be visiting after it arrived, and said he’d be happy to have a look. He grabbed a screwdriver and opened them up and to our amazement, the pedals were actually identical inside!