This is an epic jacket, and something I’ve been wanting to do for, ooh, 6-7 years at least. You see, I really liked the idea of wearable electronics, and clothes that do something and interact with their environment, so I started buying LilyPad components many years ago with the hopes of making something.

Then I realised that I know nothing about circuits and electronics, and it all seemed really confusing every time I tried to sit down and learn about it. Finally, I decided that I’d bring my suitcase of tricks (no really, I have a little yellow plastic “suitcase” with all my beginning circuitry stuff in it!) along to France on holiday and I’d sit down and teach myself how to do it then. And I actually did!

LilyPad is the sewable line of Arduino products, made especially for folks like us. They’re easy to attach onto clothes, and (apart from the batteries) are machine washable, too. For this jacket I used a LilyPad battery pack (I started with the Coin Cell one but it wasn’t quite enough power), a Lily Twinkle controller, a bunch of LEDs, and a spool of conductive thread.

I used a mix of the regular LilyPad LEDs and the Micro LEDs because that’s what I had – the micro green ones were much brighter than the bigger purple ones, but you can really only get about four loops of thread around each terminal of the micro ones, so if you need to connect it to more than two lines, go for a bigger one. The Twinkle controller is really just a tiny board with four connection spots for LEDs and makes them fade in and out randomly (though you can connect more than one LED to each spot & they’ll twinkle in unison). I wanted to make things easy for myself this time around so I left out any input sensors, though I do have an accelerometer in my stash…

I’d thought to bring along this “Fashioning Technology” book and between that and this Lilypad Twinkle tutorial, I pretty much taught myself how to make a simple circuit to do what I wanted. When I go to do my next project, I’ll need to read a few different chapters and watch some more tutorials, I’m sure!

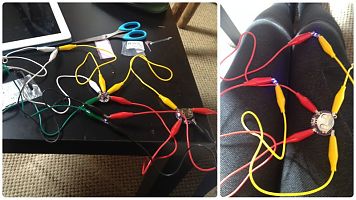

I first tested out my electronics circuits by drawing it out with pencil and paper, and then hooking everything up with alligator clips. I swear I did a dance around the room when the first little LED lit up – magic! After I was fairly confident that my circuit idea was okay, I put some scrap fabric in an embroidery hoop and used the conductive thread to hand sew all the components together and check I could still attach everything okay (and it was here I noticed how tiny the holes on the micro LEDs are!).

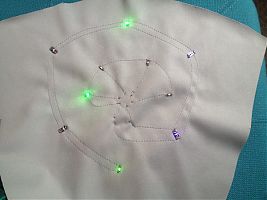

When I got home, I plotted out my full circuit for how everything would fit onto the Middle Back piece of my Steffi jacket pattern. I’d decided I wanted the battery pack to be concealed in a pocket so I could turn it on and off easily, plus be able to disconnect it (and potentially transfer one battery pack between a bunch of different projects). So rather than running to a battery, my circuits ended on two metal snaps, where the battery wires would then connect. I ran a line of LEDs directly off the snaps, which would stay solidly lit, and then a line to the Twinkle controller, with an LED running off each spot on that – these are the ones which twinkle and fade.

For the jacket, I wanted everything to be on the inside except the LEDs, so I hand-wound a bobbin with conductive thread and used matching grey thread in the top of my sewing machine. I then just sewed a line between each of the components, keeping very long thread tails at both ends. I’d pull both tails to the inside, tie them off, trim the non-conductive thread, then thread the conductive tail into a hand sewing needle so I could sew it around the LED, snap, or controller. I’d take a few loops around to make sure the connection was tight, then knot it off, and seal with some Fray Check.

Looking at my circuit, you can see there are a lot of ends to secure! It pretty much took me an entire day to sew the circuit onto the Middle Back piece, and I checked it periodically by attaching a battery pack with alligator clips so I knew it was working, too!

Once the main circuitry was done, I sewed up the jacket as normal (more on that later this week). When it was completely sewn, I sewed two elastic loops between the pocket and the snaps to hold the wire in place, and snipped a small hole into the pocket bag – it only needed to be large enough to pass a snap through, not the entire battery pack!

I was planning on attaching the battery to the circuit with the same conductive thread, but James pointed out that there was likely a lot of resistance in the thread and that the LEDs would likely be brighter if we used a shielded wire in between instead. So he helped me solder a wire to the battery pack, but then the snaps had some sort of coating the solder didn’t like, so I had to loop the ends of the wire and use conductive thread to join them to the snaps.

But I know it’s boring looking at still images when something twinkles and fades, so we recorded this short video on YouTube so you can see how the LEDs light up!

Sorry about the vertical video – we weren’t thinking when we recorded it!

Stay tuned later this week for Part Two – the sewing of the jacket!